The utilization of virtual construction in all of Haydon’s projects is nothing new. However, with our in-house Building Information Modeling (BIM) subsidiary, H3D Solutions, LLC, we can provide numerous services to our clients, ultimately making our work safer, more consistent, cost effective, and accurate.

In a digital world, the use of virtual construction and 3D modeling using H3D Solutions is needed now more than ever. H3D Solutions enables us to bring concept and design to life and keeps our client involved throughout the process.

BIM and virtual construction allow collaboration between the owner, general contractor, architect, and subconsultants to streamline communication. With tools such as these, we improve cost estimates and schedules and validate design.

“Back in the day, it was pen to paper. You physically needed to get the duct sizes, fixture sizes, and sketch everything out by hand before giving each subtrade their path,” recalls Les Keeble, a Haydon veteran of 26 years and Vice President of Risk Management. “It took a lot of coordination and effort. However, technology has come a long way, especially with virtual construction and BIM coordination, which take out the human error and make the process a lot quicker, ultimately lowering our risk, and our client’s risk on all projects.”

Continuously growing our in-house technology allows us to deliver our projects on time, within budget and provide a better product to the clients and owners. Here are just a few that we are using to serve our clients and communities.

3D modeling

With Revit, a software tool used to model intelligent components of a structure, we can give each piece of equipment a “brain” in a digital design. For example, a toilet knows it’s a toilet; a light switch knows it’s a light switch. Objects can “talk” to other objects. If one object changes within the design, other dependent objects will follow suit. This integrates and connects all pieces within the design. The result allows the team to transpose the designs from the architect and engineers into a fully constructable model.

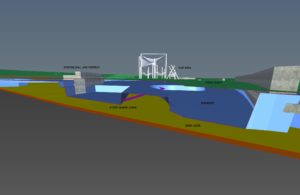

Margaret T. Hance Park Improvements

Margaret T. Hance Park Improvements

On this project for the City of Phoenix, H3D Solutions modeled the park amenities in conjunction with the underground infrastructure to fit the wet and dry utility layout within the bounds of the complex geofoam structure that supports the park above the underpass decking. This kept the structural integrity of the geofoam intact and will allow for a longer and more stable structure for the life of the park.

Clash coordination

From the Revit 3D models, we bring the architecture, structure, and trades’ models into a review software called Navisworks. It is examined by the team for potential collisions before any work is started. This process takes place on a weekly basis. With this, the H3D team and field personnel can detect errors before they occur, ultimately improving schedule and increasing productivity.

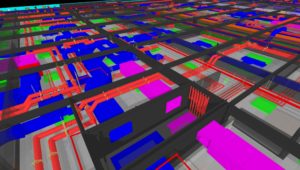

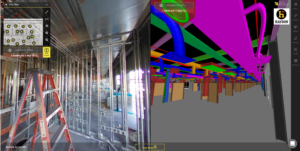

Banner Health at Aspera

Banner Health at Aspera

Haydon fully coordinated all mechanical, electrical, plumbing, and fire protection (MEPFP) systems, including the chilled beam system and all associated mechanical piping into a detailed design. Systems and wall layout were back-checked against the model with robotic total station, and the installation was checked for accuracy and completeness with LIDAR laser scans bi-weekly throughout overhead construction.

Specific attention was paid to mechanical rooms and underground stub-ups for the imaging suites early in coordination and construction allowing Haydon to absorb the entire length of coordination in the construction schedule, allowing the time to coordinate a complex building for more than 14 weeks and completing the project on schedule.

Laser scans and 360-degree photos

Weekly walks with the 360-degree camera document progress and allows the team to go back in time to review items of concern. This allows the team to set up way points throughout the building for photos to be taken in the same place each week. With this, we can track and document project progression, survey existing conditions, and give our client real-time updates.

Northwest Medical Center Post-Acute Center of Excellence

Northwest Medical Center Post-Acute Center of Excellence

Using this technology, the project team could see the mechanical, electrical, and plumbing coordination and compare to actual site conditions in real time without being onsite. This was an integral process during the pandemic because of flight restrictions due to COVID-19 and our owner not being able to travel. This technology allowed us to always keep the owner updated.

Drone photography and topography

One of our added services includes the use of the Propeller software for drone mapping and analytics, reducing our processing time from roughly two weeks to two days. We are already seeing the benefits of this tool for our clients. For one, we can fly the site for existing conditions and compare them against design during preconstruction, allowing Haydon to create more accurate estimates.

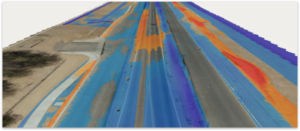

Val Vista Road improvements

Val Vista Road improvements

For this project, we compared the current grading against the design final grading model. What is depicted here is a heat map comparing low grade (blue) to high grade (red). As grading becomes level, the heat map shows the image itself. For this project, grading is within tolerance for about 90 percent with minimal clean up in the drainage channels.

Using virtual construction and BIM with H3D Solutions, Haydon can plan and build a projects long before construction begins. It ultimately provides faster and clearer information, allowing all team members to work collaboratively and commutatively as the evolution of technology in construction pushes forward.